SUPERDOME SCAN-TO-BIM

2020 | New orleans, LOUISIANA

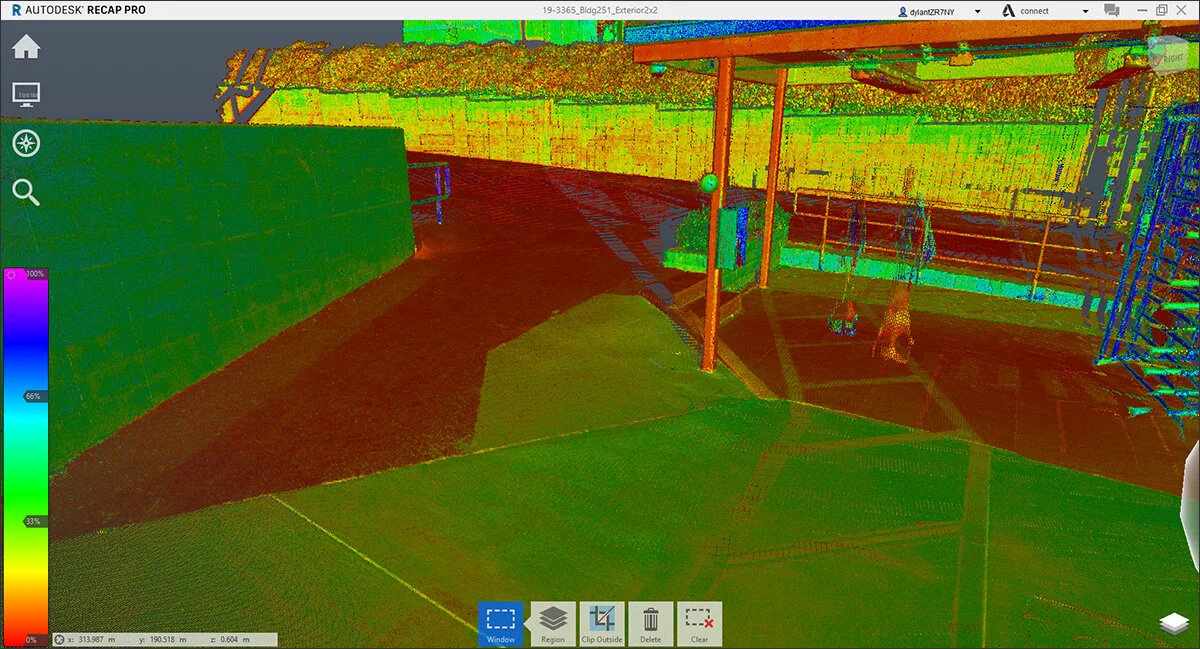

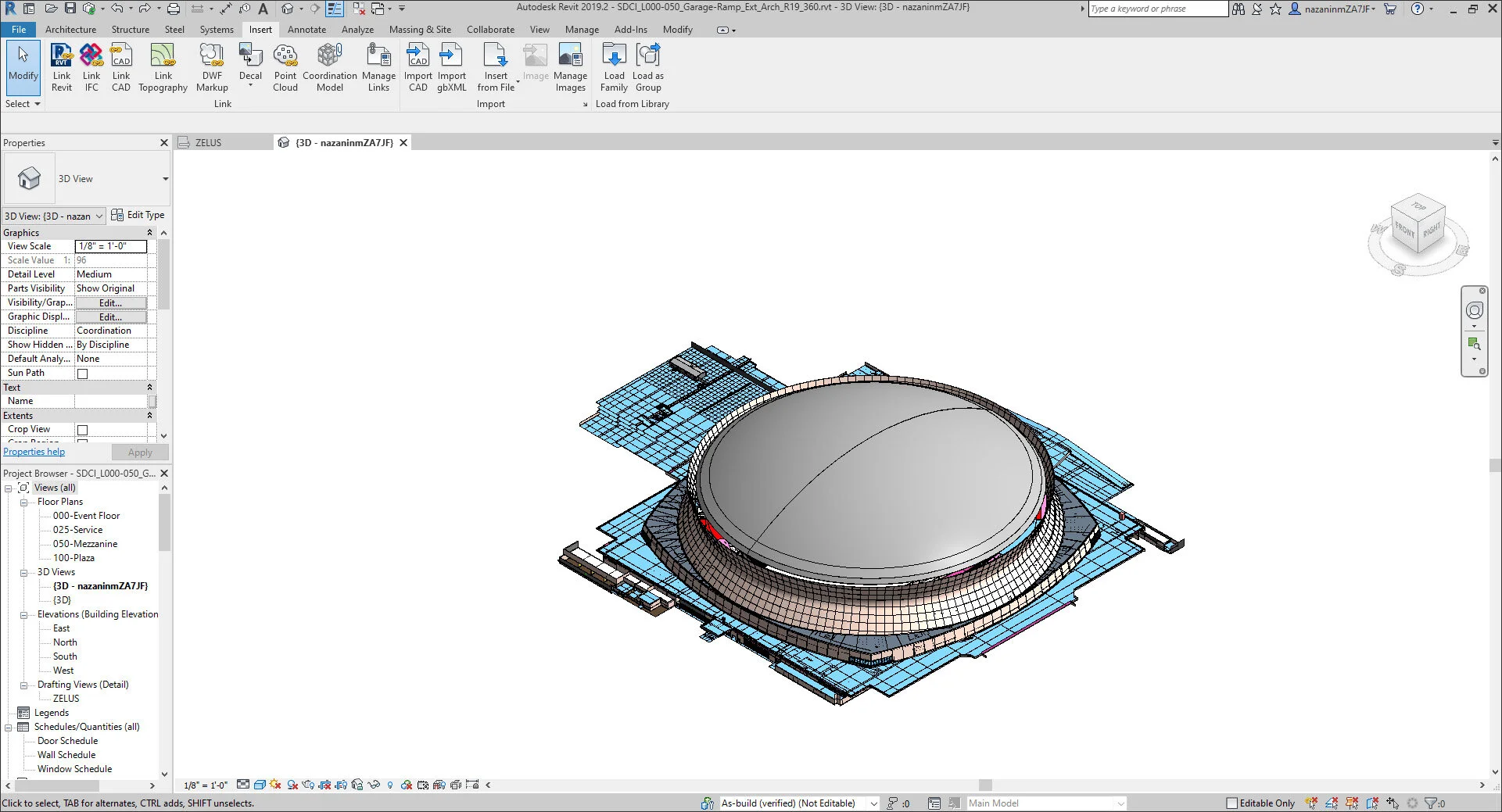

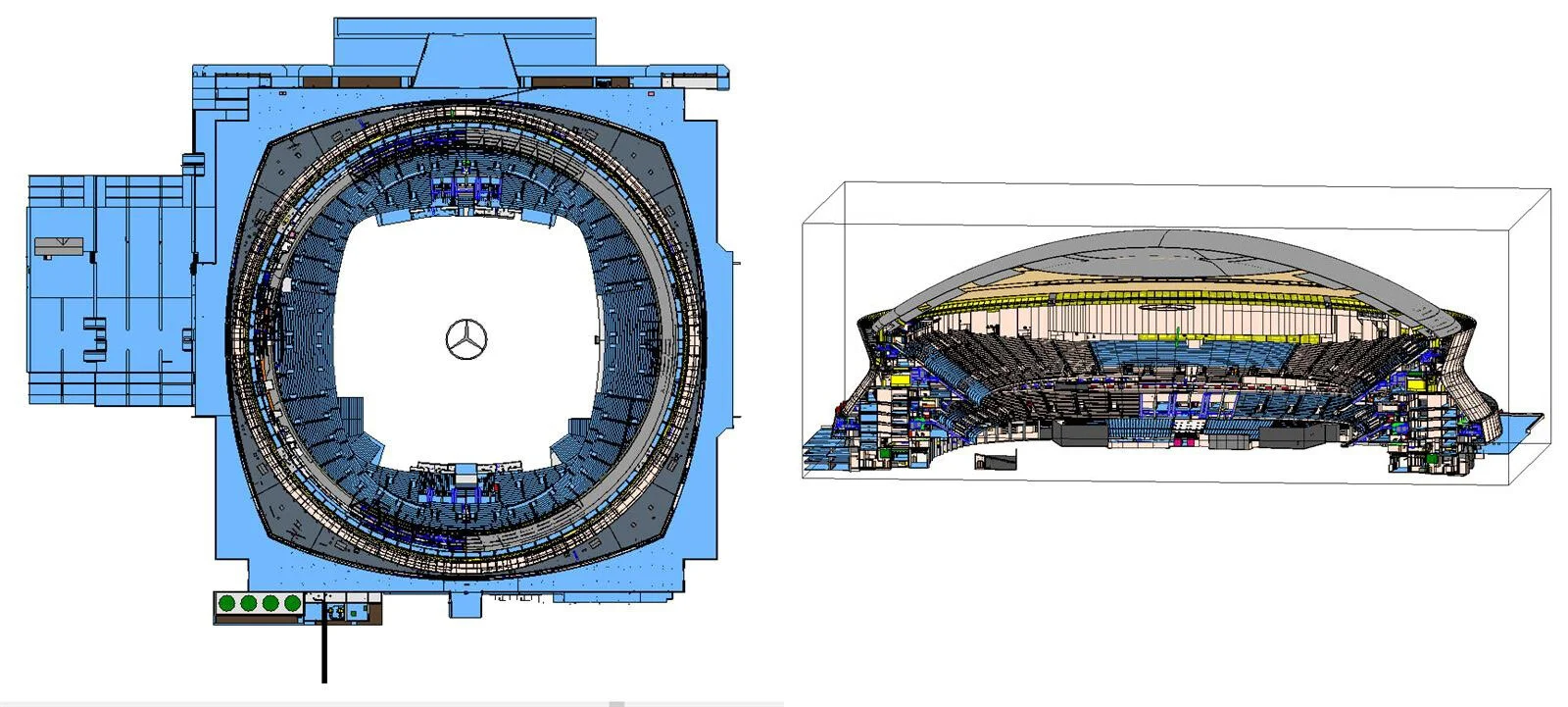

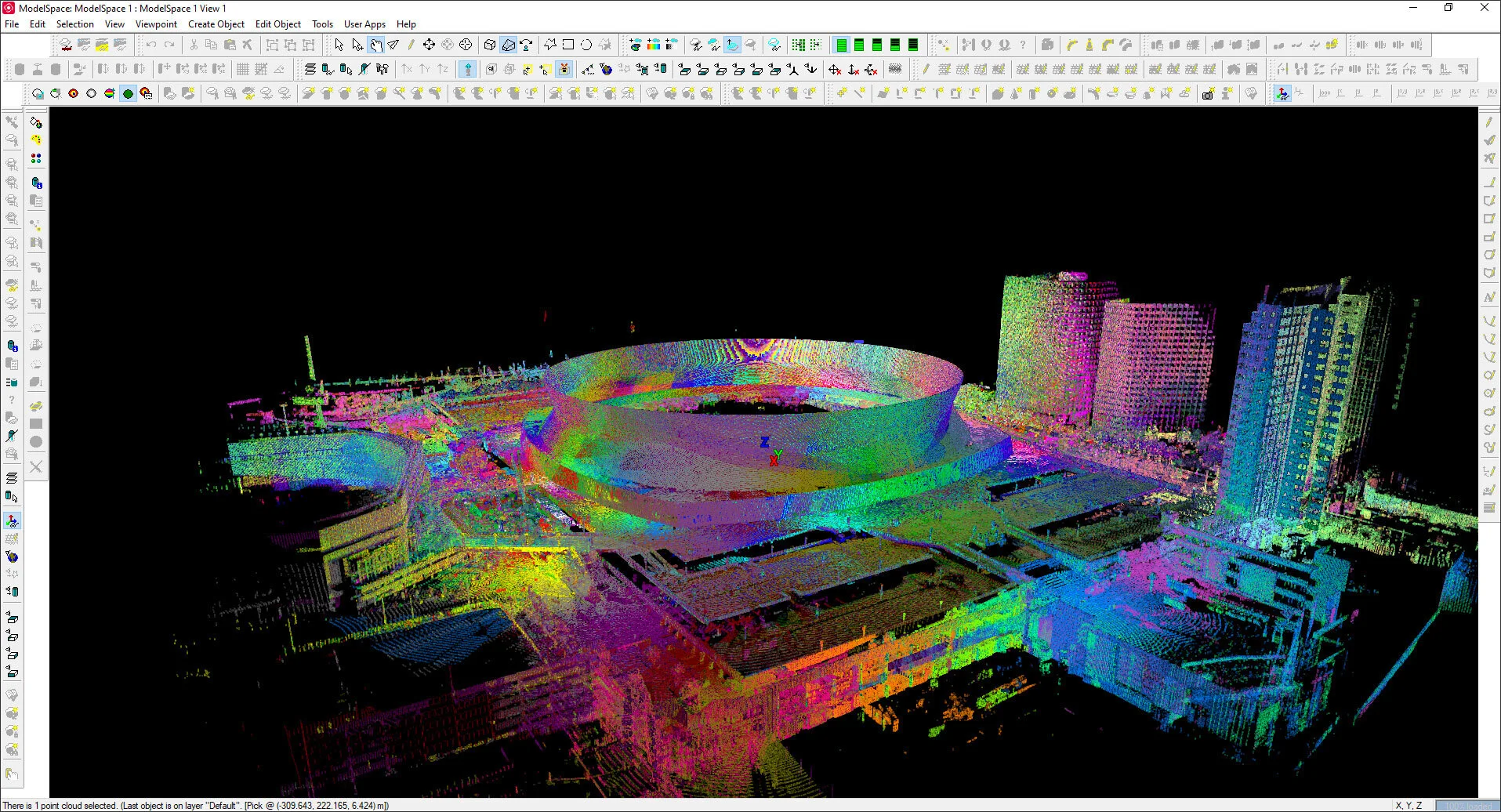

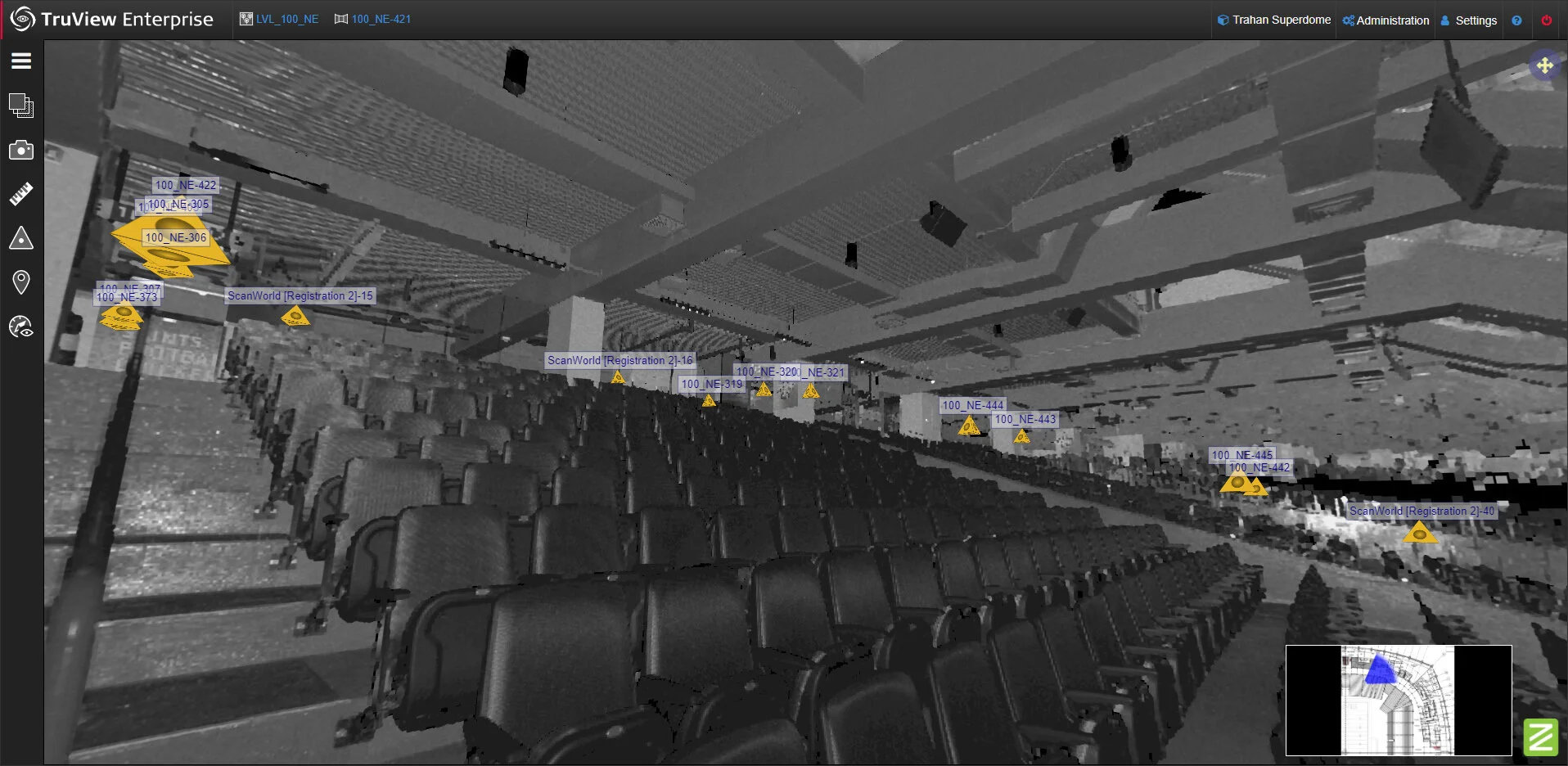

The Mercedes-Benz Superdome, built in the 1970s, is one of the most iconic sports stadiums in the country and the world’s largest entirely steel-constructed arena unobstructed by posts or columns. The current 450M multi-year, multi-phase renovation of the Superdome began in 2019 as an expansive interior overhaul meant to enhance the quality of the spectator experience. However, the architect, Trahan Architects, encountered a significant challenge at the start of the project’s design and construction: the architect had original drawings, CAD information, and BIM information that did not fully align with the Superdome’s existing conditions. For phase one of the project, both the owner and architect recognized the value of having accurate existing conditions, and selected MADE, along with CICADA, M3, and Zelus, to scan and model the areas included in the renovation.

The Superdome is a complex structure composed of 20,000 tons of steel and spanning roughly 2.6 million square feet. Scan-to-BIM provides a highly accurate model—within 0.5-inches accuracy—for all stakeholders, in order to inform decision making and to eliminate field verification trips, thereby significantly reducing the cost and schedule. Working collaboratively, thirteen teams from New Orleans, New York and Arizona, including contractors, architects, and engineers, were able to complete phase one of the project within just a few months.

Team:

Principal in Charge:

David Merlin

Project Team:

Phillip Geiman, Camille Bernsten, Stuart Hurt, John Mouton

Collaborators:

Client:

Trahan Architects

Prime Consultant:

Zelus

Joint Venture Collaborators:

CICADA

M3 Design Group